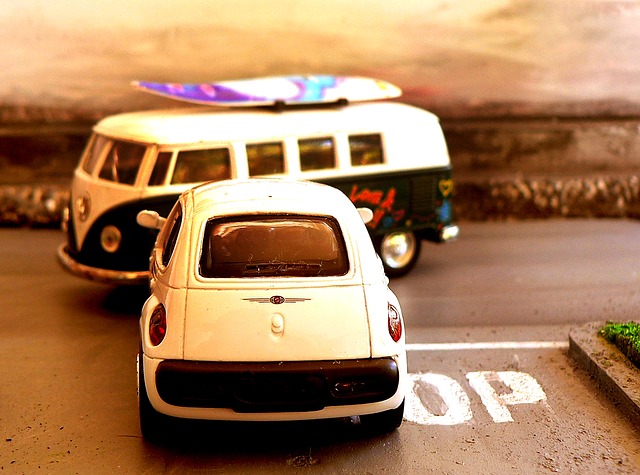

Pearl finish restoration is an intricate art that revitalizes the lustrous, iridescent appearance of vehicles' surfaces. Susceptible to chipping, fading, and loss of luster, this delicate coating requires careful techniques during restoration. Involving precision tools, cleaning solutions, and multiple coating layers, professionals transform damaged pearl finishes into aesthetic perfection. Restoring a pearl finish demands assessment, preparation, repair, polishing, and sealing for optimal results.

“Unveil the timeless elegance of your pearl finishes with our comprehensive guide to restoration. This article is your ultimate resource for restoring and preserving these delicate surfaces. From understanding the various types of pearl finishes and their unique vulnerabilities, to a detailed exploration of the restoration process—tools, materials, and techniques—we provide a step-by-step approach for effective planning. Master the art of revitalizing your pearl finish with our expert tips and ensure its longevity.”

- Understanding Pearl Finish: Types and Their Vulnerabilities

- Restoration Process: Tools, Materials, and Techniques

- Step-by-Step Guide to Effective Pearl Finish Restoration Planning

Understanding Pearl Finish: Types and Their Vulnerabilities

Pearl finish is a beautiful yet delicate coating that has been a popular choice for vehicle bodies and interior components since the early 20th century. It’s characterized by a lustrous, iridescent appearance that shifts colors based on the angle of view. While pearl finish adds a unique aesthetic appeal, it also comes with specific vulnerabilities.

There are several types of pearl finishes, each with its own distinct characteristics and weaknesses. For instance, traditional two-tone pearl paints are susceptible to chipping and fading over time due to their layered structure. Modern single-stage pearl coatings, while more durable, can still be damaged by harsh cleaning products or stones, revealing a loss of luster that requires meticulous restoration. Understanding these vulnerabilities is crucial for planning an effective pearl finish restoration for your car restoration, auto glass repair, or vehicle restoration projects to ensure the restored surface not only looks as good as new but also stands the test of time.

Restoration Process: Tools, Materials, and Techniques

The process of pearl finish restoration involves a meticulous approach to revive the luster and aesthetic appeal of surfaces adorned with this sophisticated coating. This intricate task requires a tailored set of tools, high-quality materials, and specialized techniques. At the core of successful pearl finish restoration lies a deep understanding of the unique properties of pearl coatings. These coatings, known for their iridescent hues and depth, demand precision during the restoration process.

Professional auto body shops equipped with advanced vehicle repair services employ a range of tools, from fine-grit sandpaper for gentle yet effective smoothing to precision paint brushes for precise applications. Specialized cleaning solutions are utilized to remove dirt, dust, and debris without compromising the delicate finish. The technique often involves multiple layers of coating, each applied with meticulous care, followed by curing processes that allow the pearl finish to reach its full potential, transforming faded or damaged surfaces into a stunning spectacle.

Step-by-Step Guide to Effective Pearl Finish Restoration Planning

Restoring a pearl finish involves meticulous planning to achieve a flawless result. Here’s your step-by-step guide:

1. Assess Damage and Scope: Begin by thoroughly inspecting the pearl finish surface. Identify chips, scratches, or discolouration. Determine if it’s limited to minor imperfections or requires complete vehicle body shop services for a full restoration.

2. Gather Materials & Tools: For effective pearl finish restoration, you’ll need specific tools and materials tailored to this finish. This may include specialized polishes, compounds, waxes, and applicator pads. Remember, the right tools make all the difference in achieving a smooth, glossy finish.

3. Prepare the Surface: Before restoring, wash and decontaminate the surface to remove any dirt or residue. Ensure the area is clean and dry. Sanding may be necessary to smooth out minor imperfections, but be careful not to over-sands, as this can damage the pearl finish.

4. Repair & Fill: Fix any deep scratches or holes using appropriate body shop services and fillers designed for pearl finishes. Allow ample time for drying before proceeding.

5. Polish and Buff: Apply a high-quality pearl polish using circular motions to restore the shine and reveal the finish’s depth. Buff gently with a soft cloth to achieve a smooth, glossy surface.

6. Apply Top Coat: Finalize the restoration process by applying a protective top coat designed for pearl finishes. This will enhance durability and maintain the vibrant appearance.

Pearl finish restoration is an art that requires careful planning and a deep understanding of the material. By familiarizing yourself with different pearl finish types and their vulnerabilities, and employing the right tools, materials, and techniques, you can successfully revive and preserve these exquisite surfaces. Following our comprehensive step-by-step guide ensures a systematic approach to planning, allowing you to achieve professional results in your pearl finish restoration projects.